Milling machines are designed to effectively cut, shape and drill various machine parts with the required precision needed for industrial applications. These essential tools are needed to maintain industrial facilities, offshore platforms, and marine vessels safety and productivity. Read on to discover where and why these tools and services are needed.

Milling machines are metalworking tools that are highly effective at working the material to desired specifications. They can be used for material shaping, cutting, and finishing operations on metal components. Milling machines can be equipped with various tools, such as drill bits, end mills for deeper keyway cutting, slotting and counterboring operations.

These tools are primarily used in sectors requiring absolute precision with machined parts. This reliable accuracy is applied at either the components' initial manufacturing or later during maintenance periods.

Milling machines use various rotary cutters to remove unwanted material from the work pieces. Milling differs because the designated tools will have several cutting points compared to a standard drilling operation.

Milling machines stay perpendicular to the object's axis, and the cutting is generally localised to the cutting on the tool's edge. At high speeds, these tools will remove material from the workpiece, known as swarf, forming the material to the desired shape or surface finish. The unique nature of these milling tools also enables engineers to repair the edges of a workpiece or create indentations such as slots, pockets or grooves.

Two main aspects must be monitored when using milling machines: the feed rate and cutting speed.

The feed rate relates to the speed at which the cutter moves through or along the workpiece during a milling operation; a slower rate will increase accuracy and produce a better surface finish, and a higher rate will be faster, impacting the tool’s longevity. The feed rate is determined by a combination of factors, including the machined material, the cutting tool's type and size, the cut depth, and the desired surface finish. In general, a smaller cutting tool or a deeper depth of cut will require a lower feed rate, while a larger cutting tool or a shallower cut will tolerate a higher feed rate.

The cutting speed refers to the speed of the tool rather than the movements of the whole machine tool. Similar to the feed rate, this will have to be dictated to suit the context of the current operation. It can be pre-calculated on-site to suit the specifics work with this formula:

Cutting Speed (SFPM or m/min) = (pi x tool diameter x spindle speed) / 12 (for SFPM) or 1000 (for m/min)

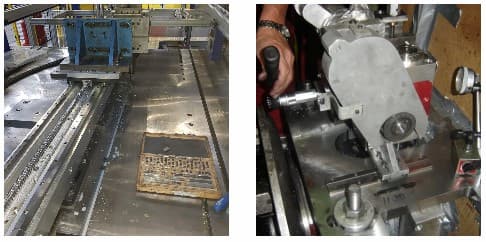

An on-site milling machine has the added convenience of being used at the machine's location instead of at a remote facility with a static milling machine. However, no single milling machine is used for every application; they must be customised to suit specific milling needs with different slides, feeds, milling heads and power options available to suit the application and space envelope.

Portable milling machines: These machines are designed for heavy-duty milling operations on large components, such as turbines, generators, motor pads, joint faces, seating faces, beams, columns, frames, bedplates, casings, heat exchanger partition plates and diesel engine entablatures & bedplates. They are often used in oil and gas, power generation, and shipbuilding.

Relying on remote component repairs always involves long delays as the parts must be removed, transported, repaired and returned. This creates significant downtime for your machines as well as logistical concerns related to your part’s safety when travelling.

Choosing In-Situ (on-site) milling provides managers with maintenance and emergency repairs at your location without any additional complications.

At In-Situ Machining Solutions, our expert team of engineers are trained with a broad range of highly effective on-site machining equipment, including in-situ milling. A range of specialist interchangeable milling equipment can be prepared to meet the specific requirements of each job, meaning a cost-effective engineering solution can be found to support our clients whilst minimising downtime. Contact us to discover which of our other services will help you improve productivity at your business.