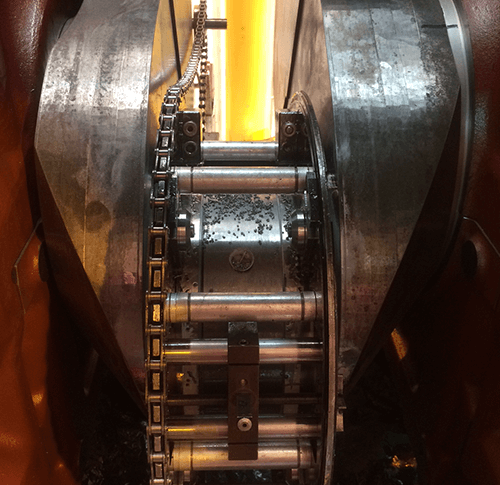

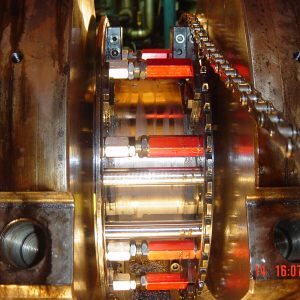

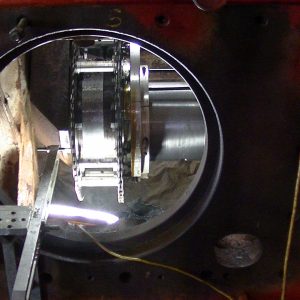

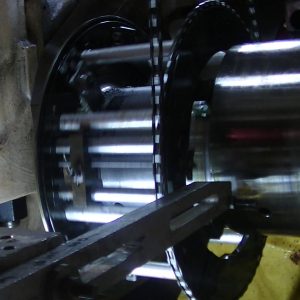

With over 20 years of experience, our highly trained engineering teams offer expert onsite machining services. We specialise in refurbishing crankshaft machinery, crankpins, and main bearing journals during planned maintenance or emergency breakdown situations.