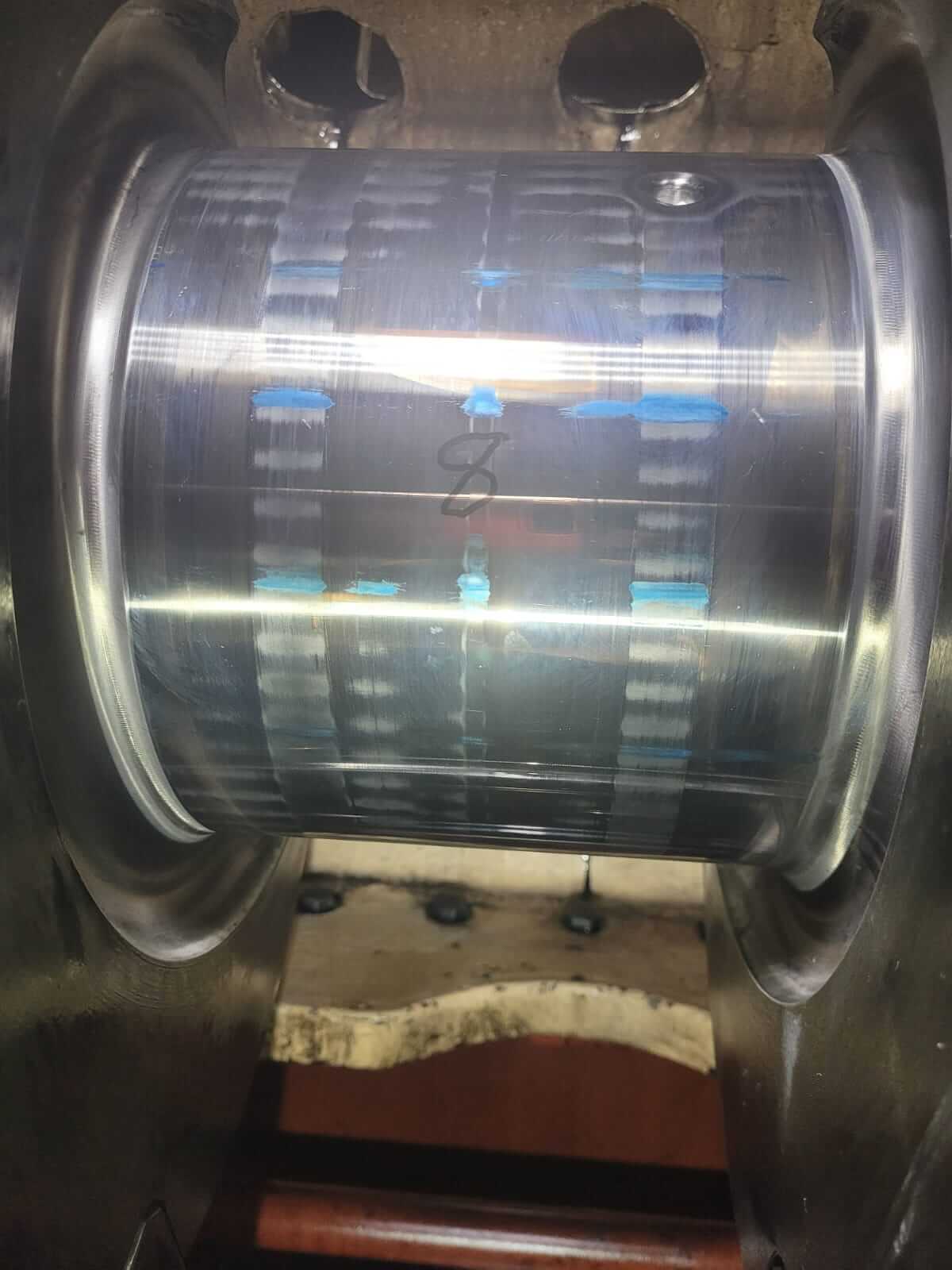

This phenomenon develops over time and manifests itself in an uneven wear pattern that is, with the right tools, easily detectable as a protruding band (“cam”) that goes around the circumference of the crank pin. It usually only develops on engines equipped with grooved bearing shells and its development is a function of time. The more impurities (abrasive particles) the lubricating oil contains, the faster the cam effect develops.