Our expertise in shaft journal and journal repair has earned In-Situ Machining Solutions a global reputation. We specialise in onsite machining for repairs to rotating equipment, including main bearing journals, fan shafts, alternator shafts, and more.

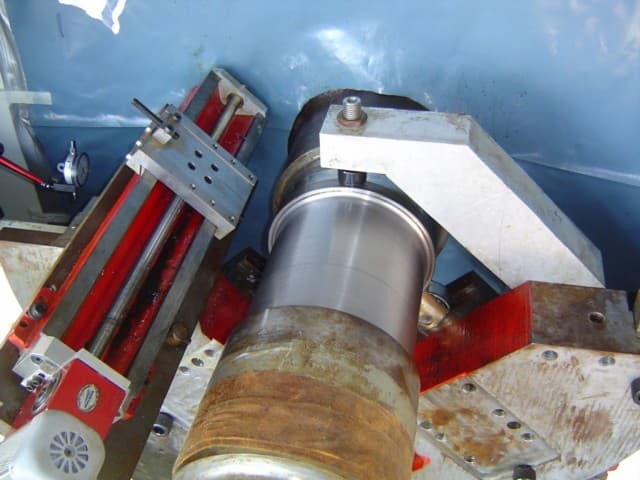

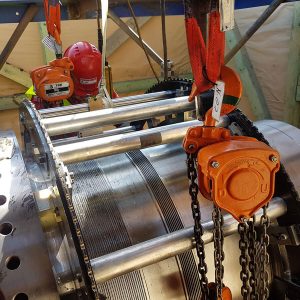

Rotating equipment can suffer damage from oil starvation and major seizures. We deploy purpose-built orbital equipment and onsite machining techniques to provide high-quality onsite journal repair services worldwide. Our highly trained and experienced engineers excel in journal turning, grinding, superfinishing, and polishing.

By utilising our specialist teams and in-house developed systems, we eliminate the need to remove the rotating component from its housing casing or stator for repairs to the main bearing journal or separate bearing/journal surfaces. In addition to renowned diesel engine crankshaft repairs, we offer onsite refurbishment of large damaged rotating components, including shaft journals, to OEM standards.