At the request of a major rotating machine company, our expert engineers here at In-situ Machining Solutions Ltd completed the repair to a large centrifugal fan shaft bearing diameter used for hazardous area ventilation situated in one of the most northerly oil fields in the North Sea.

Removal of the impeller/shaft assembly for onshore repair was not viable due to the assembly being too large to be removed from its casing and the fan room, which housed three of these fans. The work, therefore, had to be carried out on site, offshore, where severe climatic conditions only allowed work to be carried out in three-hour stretches at a time.

The 80mm x 220mm long diameter fan shaft was damaged due to the bearing's split adapter sleeve turning on the shaft during the fan's operational speed of 750 RPM, causing extensive circumferential grooving approx 2mm deep.

The solution was to orbitally machine and polish the shaft to 75mm diameter and shrink fit a make-up sleeve of 2.5mm wall thickness onto it, enabling the shaft diameter to be brought back to its original 80mm.

A series of roughing cuts were taken along the shaft initially, followed by a finishing and polishing operation prior to shrinking on the pre-made make-up sleeve.

An allowance of 0.5mm was left on the outside diameter of the make-up sleeve to finally machine and polish the 80mm to the limit size requirement; this would allow the fitting of a new split spherical roller bearing arrangement.

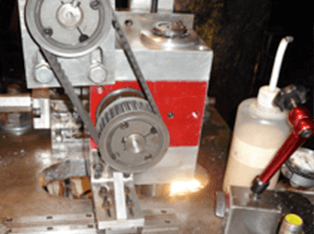

Due to limited radial access to the shafting, the In-Situ design team produced a special small series of orbital turning machines, associated attachments, and tooling to add to its extensive standard range of larger machines.

All work was carried out according to our customers' and end users' specifications, then inspected, and finally passed off to their check prior to the team's demobilisation from the site.

What sets In-Situ Machining Solutions apart is our adaptability. We understand the unique challenges that arise in offshore environments, and our onsite machining service is specifically designed to cater to these demands. Regardless of your location, we have the flexibility and expertise to serve clients worldwide with precision and efficiency.

You can explore other examples of our team's expertise in our case studies, such as:

Discover for yourself the incomparable benefits of partnering with In-Situ Machining Solutions. Contact us today to discuss your requirements, and let us provide you with a bespoke solution tailored to your specific needs.