Twenty upper liner landing seal surfaces and one lower liner bore have been completed at the port of Algeciras in southern Spain.

Due to severe cylinder block corrosion leading to operating problems after thousands of working hours it became apparent that the liner landing surfaces of the cylinder block had to be refurbished before a major failure occurred.

In-situ Machining Solutions (UK)Ltd. were contracted by the engine manufacture to carry out this modification/repair work.

Working to the OEM’s repair specification each of the V20 upper liner landing register bores were machined oversize to a specific size to accept new liners. In addition to lightly skimming the upper liner landing seal face adjacent to the newly machined bore.

The repair to the lower liner landing register took the form of fitting a make-up sleeve into the lower bore to make good the damage in this area. This bore had to be machined 12mm oversize to accept the make-up sleeve which was drawn/jacked into the bore and sealed and secured using a retaining compound and grub screws. Once secured, the make-up sleeve bore was finally machined to design size.

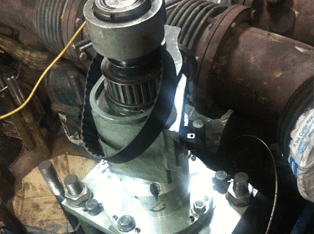

In-situ machining Solutions used one of their in-line boring/facing machines to conduct the work together with associated tooling and calibrated measuring equipment.

Prior to the work starting all internal parts of the engine were masked off to prevent ingress of swarf and debris entering the working parts of the engine during the on board machining process.

To remove the engine from the vessel for repair was unthinkable due to the busy scheduling of this Ro-Ro ferry added to which the enormous cost to extract the engine and transport it to be serviced at a factory on-shore was out of the question.

To carry out this work on board the vessel amounted to vast cost savings with no disruption to its’ sailing schedule.

All work was carried out during the night shift to accommodate the busy scheduling of the 99 metre long catamaran.

The end result of this project was extremely successful and took 14 days to complete much to the complete satisfaction of the OEM and vessel operator.