In-Situ Machining Solutions Ltd have, at the request of a major diesel engine manufacturer and South American utility company, successfully completed the repair to a damaged timing gear locating diameter and drive keyway of a large four-stroke diesel engine. Such was the damage to the shaft diameter and drive keyway that the timing of the engine seriously affected the performance of the diesel generator.

The integrity of timing components in a large four-stroke diesel engine is paramount for optimal performance and efficiency. The timing gear locating diameter is a critical component that ensures the proper alignment and positioning of the timing gear on the engine shaft. Any damage to this diameter likely results in misalignment of the timing gear, leading to improper timing of the engine's valves and fuel injection events.

With the drive keyway damaged, the connection between the gear and the shaft becomes compromised, leading to erratic movement of the timing gear. This erratic movement further disrupts the engine's timing sequence, causing irregular combustion events, increased vibration, and accelerated wear on engine components.

When both components are damaged, the engine may experience frequent stalling, uneven power delivery, and increased downtime for maintenance and repairs.

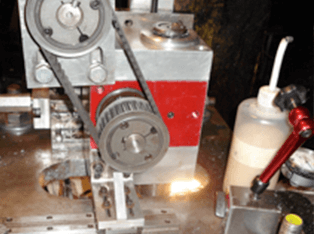

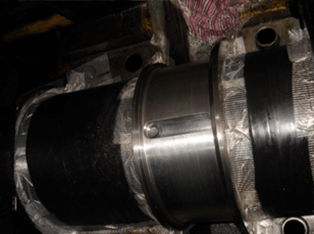

The solution to the problem was to machine the 340 diameter undersize by 3mm to remove fretting and wear. We also machined the new drive keyway 32mm wide x 12mm deep and 180˚ diametrically opposite to the damaged keyway, which had worn progressively over time from 32 to 44mm wide.

For the milling work associated with machining the keyway and access limitations to the timing gear locating diameter (337mm), a special pneumatic mini-mill has been designed and produced in-house to enable this repair to take place.

All work was carried out in accordance with OEM procedures, inspected, and passed to the complete satisfaction of the utility company's management.

We have conducted thousands of successful on site machining operations across every continent and in 76 different countries, providing a far more efficient repair service than the alternatives where damaged parts need to be sent away. Here are additional relevant case studies detailing other successful work we've conducted for businesses globally:

We at In-Situ Machining Solutions Ltd are a company renowned globally for our expertise and precision work associated with on site repairs and, in particular, planetary or orbital machining of stationary, rotating machinery bearing diameters and journals in the range 50 to 1100mm.

We pride ourselves on combining our expertise with ISO 9001 for quality, ISO 14001 for environmental protection, and ISO 45001 for on-site occupational health and safety to provide you with the best repair team to work within even the most extreme environments. Our team's experience guarantees that we will conduct the required work without being a hindrance to your daily operations.

Explore the many benefits of partnering with us for your emergency engine and machine repair by exploring our many services online. Contact us today to discuss your requirements, and we'll tell you how we will successfully resolve them.